Injecting the chemicals required in the appropriate formulation into the sponge casting machine with a moving conveyor structure with the help of pumps constitutes the sponge production line. Our products, which we produce in our polyurethane foam casting line, contain 5% recycled rubber. It is very important for production that the ambient conditions comply with the standards. The blocks prepared after casting are cut in precision machines at the desired thicknesses. The cutting process is completed in balls with an average length of 30 meters and a width of 1.5 meters and delivered to our customers as rolled up balls.

Orthoflex

Our Orthoflex sponges are highly preferred in the production of insole because they are open-celled, antibacterial, perfumed and durable due to their high flexibility.

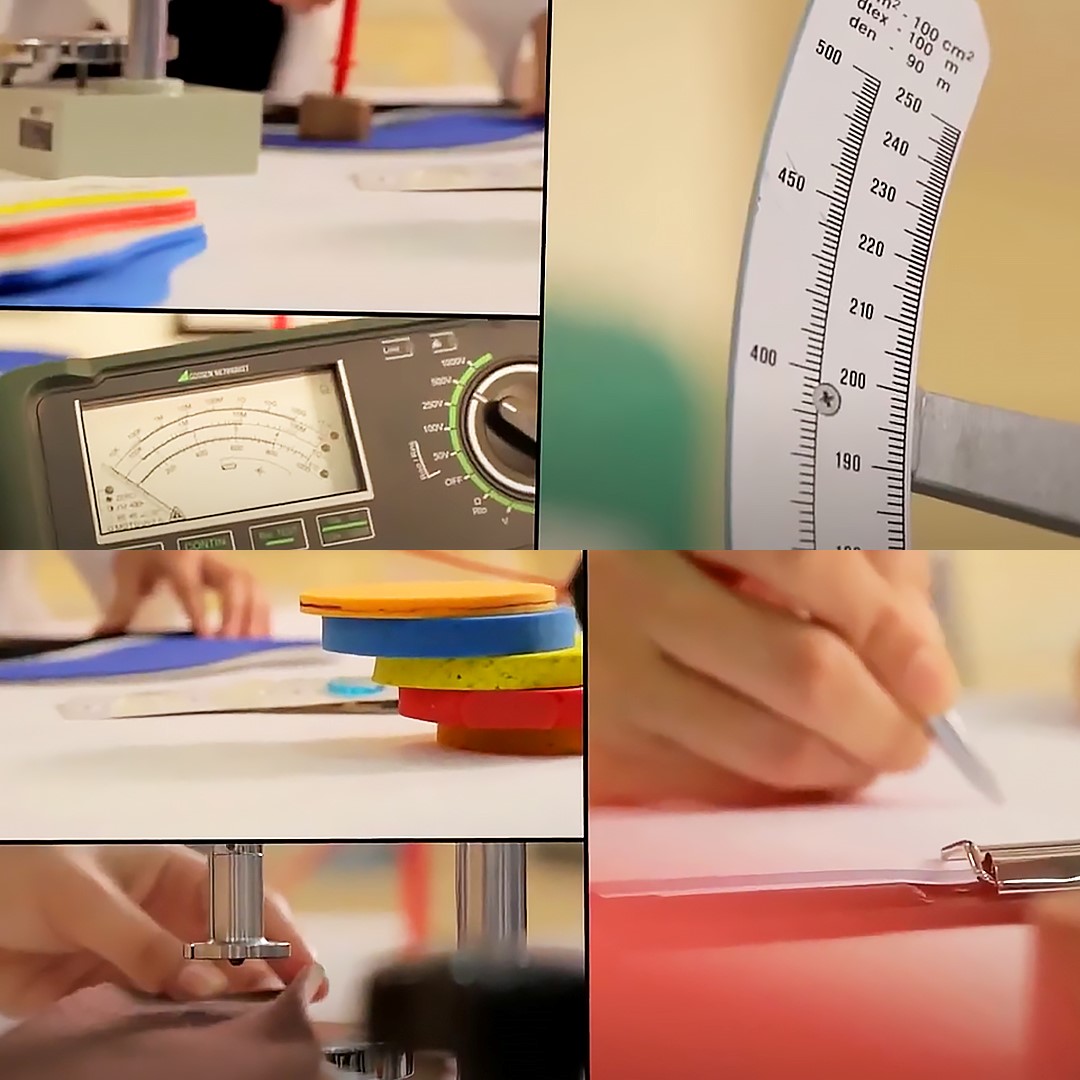

Density and hardness tests and sponge quality measurements are made to ensure customer satisfaction at the highest level. Our products can be made in the desired color, with or without perfume, and they also have antibacterial properties.

Our standard production ranges are in the table below.

| PRODUCT NAME | DENSİTY (kg/m3) | SHORE C | THICKNESS (mm) |

| Orthoflex MDI | 95 ± 10 | 25 ± 5 | 2-20 |

| Orthoflex MDI | 80±10 | 20±5 | 2-20 |

Our Production Colors

It is widely used as an insole in the shoe industry, especially for work shoes.