TPU is a polyurethane thermoplastic elastomer with high wear resistance, high flexibility and easy mouldability. Our production is done in two different ways due to the density and hardness difference of the raw material. Our production, which has high flexibility, is generally on the insole, and 3 different colors and softness can be produced on one sole. The difference here is determined by customer preference.

TPE

We have models suitable for different foot structures, and the hardness of these models varies according to the region of the foot. Generally, transparent, yellow, blue, white, black and gray colors are used in the products. It is also possible to produce in different colors. Fabric, leather, sponge, etc. materials are used as coating.

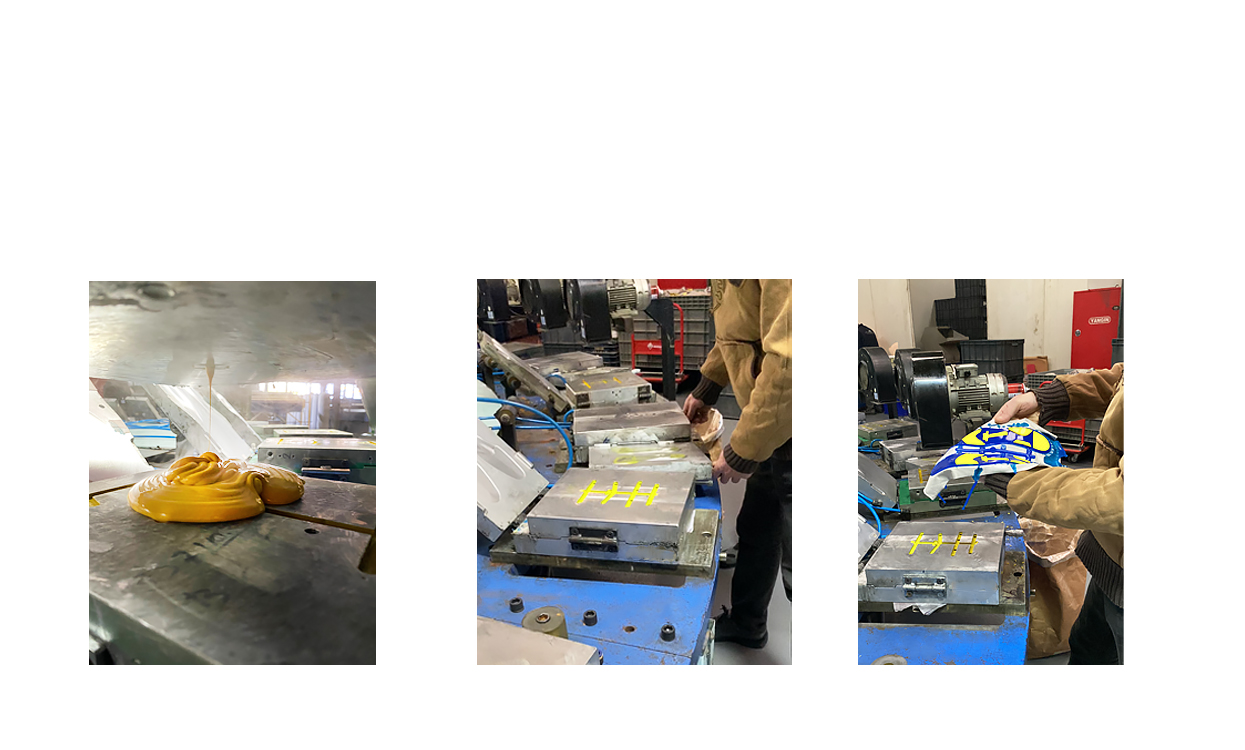

Production starts with the loading of the raw material, which comes in granular form, into the machine tank. After the technical settings in the machine are provided, the machine becomes ready for the mold casting process. Our new and state-of-the-art machines automatically cool the molds and provide the opportunity to control all the information about the product. The raw material, which comes in granular form, is melted by the high temperature in the machine. The melted raw material is cast into the mold with a certain pressure thanks to the system of the machine. After a certain period of time, the molding process takes place and the product is removed from the mold and the production here is completed.

Our production, which has less flexibility, generally supports the insole as a semi-finished product. In line with the customer’s request, different models of accessories and buckles can be produced.